The DZS series of dry vacuum pumps are a range of Class 0 certified dry claw vacuum pumps; single-stage, oil-free and air-cooled. They are available in fixed speed and Variable speed variants. The Variable speed variants have VSD+ inverter drive technology built-in.

Dry multi-claw vacuum pumps with Variable Speed Drive technology DZM 600-1200 VSD⁺

A complete multi-claw vacuum pumping system in a box. A solution perfectly designed to meet your larger process demands.

DZM VSD⁺ Series – A complete multi-claw vacuum pumping system

We offer a complete multi-claw vacuum pumping system in a box. A solution perfectly designed to meet your larger process demands with a central vacuum system based on the renowned Atlas Copco compressor philosophy. This vacuum pumping package offers a completely controllable system ranging from 44 to 1,230 m3/h integrated into one cabinet with a simple ‘plug & play’ concept.

The beating heart

At the heart of this system is the DZS 300 V claw pump providing efficiency, robustness and ultimate performance with best in class credentials. With three sizes of system available plus the option to expand the central vacuum system with centrally controlled multiple packages, we can offer a complete turn-key solution regardless of your requirements.

The DZM VSD⁺ is ideally suited for:

- Woodworking

- Product handling

- Food processing

- Filtration

Dry Claw Vacuum Pumps DZS 65-300 series

The DZS series are mono claw, dry vacuum pumps that offer simplicity, robustness, efficiency and contaminant handling capability.

Dry Claw Vacuum Pumps DZS 65-300 series

The DZS series are mono claw, dry vacuum pumps that offer simplicity, robustness, efficiency and contaminant handling capability.

DZS Series- Dry claw vacuum pumps

The new range based on Atlas Copco’s dry claw technology features an innovative design which creates a new benchmark in the claw pump market. The simplicity, robustness, efficiency and contaminant handling capability of these pumps make them the smart choice for your application. Built to the exacting standards and quality demanded by our customers, the new dry claw pump provides you with a trouble-free and cost-effective solution to meet your needs. Innovative features like the dry (oil-free) pumping chamber, low noise levels, efficient motors, compact design with a small footprint, ensure efficiency.

Designed for a long life of reliable, efficient operation

The dry claw machine boasts some fantastic design features including stainless steel corrosion resistant claws. The renowned Atlas Copco surface coating applied to the pumps process chambers has proven to be unrivalled in our compressors.

The DZS dry claw vacuum pump is ideally suited for:

- CNC routing/clamping

- Food applications

- Plastic extrusion

- Paper converting

- Pneumatic conveying

- Pick and place

- Vacuum sewage

- Printing

- Tobacco

- Central vacuum systems

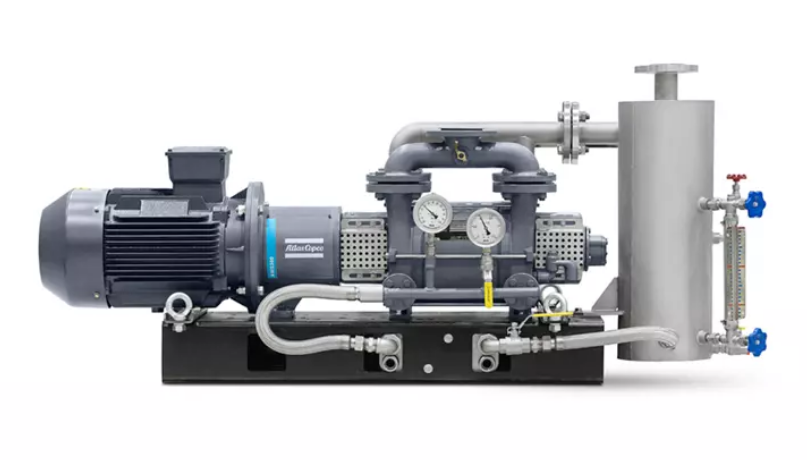

Liquid ring vacuum pumps AWS, AWD & AWL series

Thanks to a tough construction and proven operating principle, AWS, AWD & AWL liquid ring vacuum pumps from Atlas Copco are used in the most demanding environments across all sectors from food processing to petrochemical to construction.

AWS, AWD & AWL series – Suitable for a wide range of applications

The new AW series of standard liquid ring vacuum packages are perfect for use in humid, dusty and dirty environments commonly found in industrial processes. The pumps, which have a simple and study design, reliably deliver vacuum to a whole range of industries including food & beverage, dairy, mining, chemicals, oil, steel, cement, plastics, textiles and food processing. Liquid ring pumps are equipped with a fixed blade impeller located eccentrically within a cylindrical casing. As the impeller rotates, liquid (usually water) is thrown out by centrifugal force to form a liquid ring around the circumference of the casing, sealing the tips of the impeller and creating separate enclosed gas chambers between each blade. As a result of the eccentric position of the impeller, these chambers vary in volume as the shaft rotates, having the effect of drawing in and compressing process gas. The AW liquid ring vacuum pumps are available for both single and two stage pumps. AWS single stage liquid pumps are optimized for operation above 200 mbar(a), making them perfect for applications such as filtration or wet conveying, with an ultimate pressure of 30 mbar(a). Our liquid ring vacuum pumps are offered as plug & play modules or engineered systems for complex duty applications in a number of configurations and are suitable for operation in once through, partial recirculation or total recovery. For partial or total recovery systems the pump package components are offered with stainless steel wetted parts as standard, irrespective of the materials of construction of the pump. The AW liquid ring vacuum pumps are available for both single and two stage pumps. Our liquid pumps are optimized for operation above 200 mbar(a), making them perfect for applications such as filtration or wet conveying, with an ultimate pressure of 30 mbar(a). They are the perfect solution for cyclical pump down applications such as evacuation, impregnation or sterilization. AWD dual stage pumps are finely tuned machines dedicated to providing consistent high performance at operation pressures below 200 mbar(a). The two synchronized pumping chambers work in series to enable optimal performance on continuous critical process applications such as bottling, degassing, & solvent recovery.

Liquid ring vacuum pumps deliver sustainable productivity in the harshest environments including:

- Mining

- Brick extrusion

- Automotive industry

- Cement and allied products

- Chemical industries

- Food processing

- General manufacturing

- Metalwork industries

- Paper and allied products

- Petroleum industries

- Oil and gas

- Plastics

- Textile industry

- Power and utilities